GreenGrain - Green steelmaking with tailored metallurgical grains by fast heating techniques

Funders

Project information

Project duration

-

Funded by

European Structural and Investment Funds - INTERREG

Project funder

Funding amount

1 289 854 EUR

Project coordinator

University of Oulu

Unit and faculty

Contact information

Contact person

Researchers

Project description

About GreenGrain

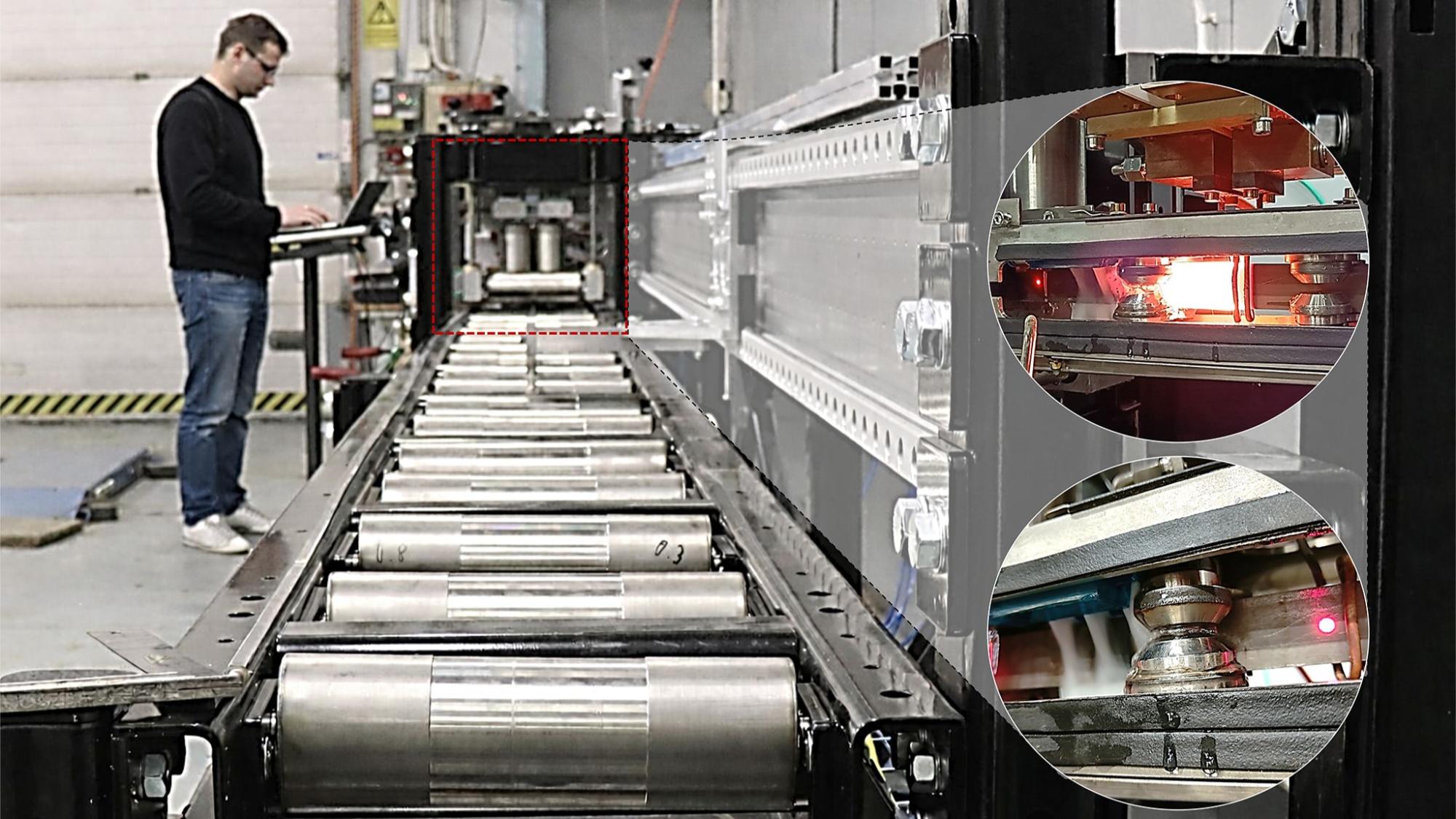

GreenGrain replaces energy‑intensive furnace routes with fast, precisely targeted heating to cut energy use and waste while boosting performance. A core innovation is layer‑scale control of properties, independently tuning the surface and core so components gain wear resistance at the surface and toughness in the bulk.

The project develops and validates induction and laser heat treatments that deliver the right temperature profile at the right depth and rate. This enables optimal microstructural transformations and cost‑efficient, sustainable production. Alongside experiments, we build a materials library and use modelling/AI to map process–structure–property links and guide industrial use.

GreenGrain’s example demonstrations include—but are not limited to—residual‑stress relief and optimisation across various structures, surface hardening of fatigue‑critical components, localised tempering, and energy‑saving, collectively accelerating the uptake of low‑emission, energy‑efficient heat treatments.

Why it matters

By bridging scientific research and industrial application, GreenGrain delivers methods industry can adopt directly supporting fossil‑free steel production and strengthening Northern Scandinavia’s leadership in sustainable metallurgy. Results will be openly disseminated via publications, conferences and a project website to maximize impact.

Partnership & funding

The lead partner is the Future Manufacturing Technologies (FMT) research group at the Kerttu Saalasti Institute, University of Oulu (FI), with Luleå University of Technology (LTU, SE) as project partner. The total budget is €1,289,854, of which the University of Oulu’s share is €889,854. The project is funded by Interreg Aurora 2021–2027 (EU‑ERDF) and the funding has been granted by Region Norrbotten, with co‑funding from the Regional Council of Lapland and SSAB.

NYPS 20373343